Modular Construction

At the same time as on-site work began at the project site, our project’s modular builder, Beracah Homes, began construction of the building modules. Because Beracah was able to transport 20 foot wide modules to the site, each home is made up of only two “boxes.”

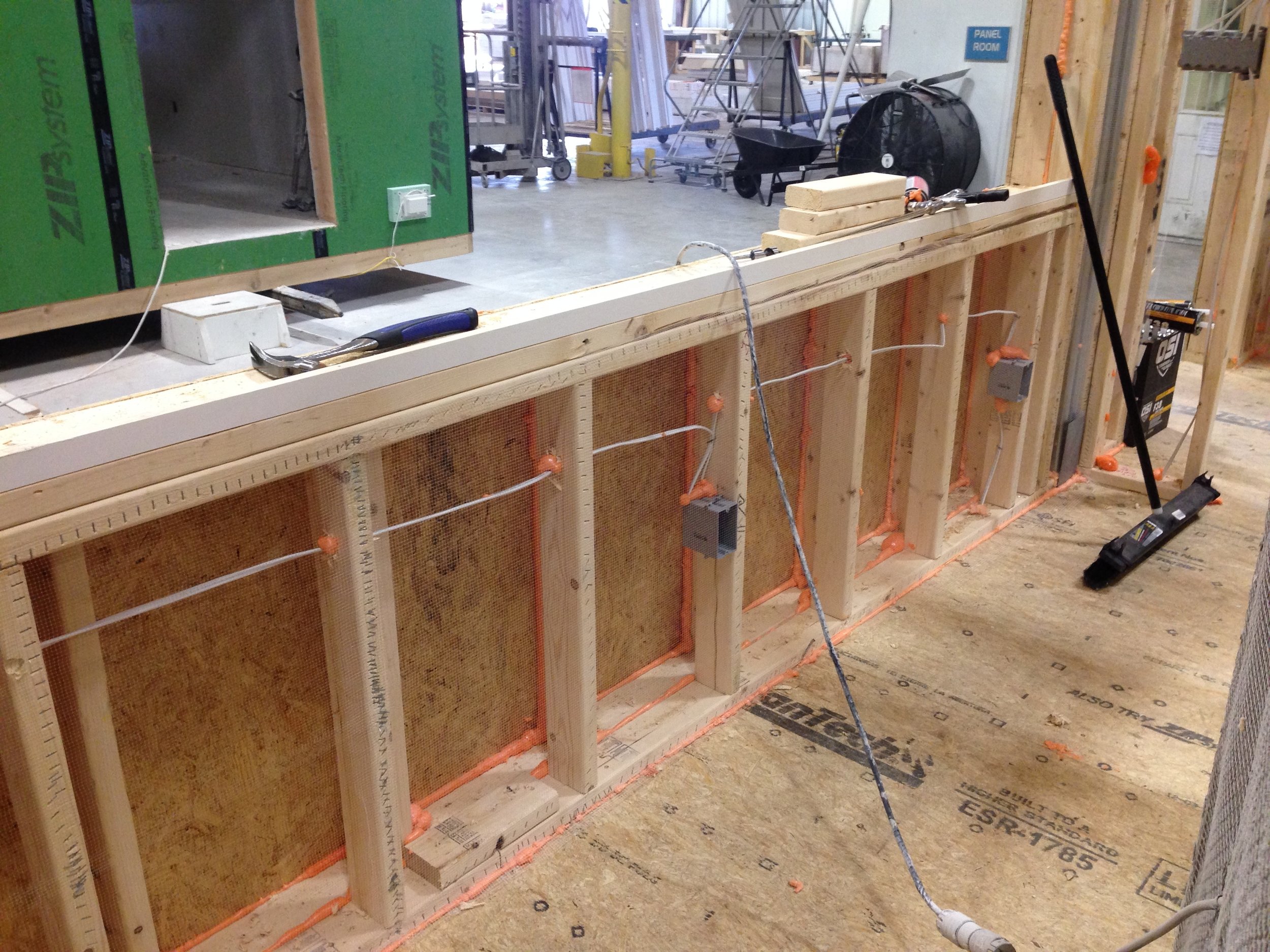

In contrast to site-built construction, where contractors often cut corners and accept poor-quality workmanship, Beracah’s Homes are built by specialized crews in a factory-controlled environment, and must withstand transit and craning into place without damaging interior finished drywall.

At Beracah’s factory, modules are assembled on two lines, and boxes are rolled down an indoor rail track as they advance to each successive stage of construction: framing, mechanicals, drywall and window installation, paint, trim/finish carpentry and prep for transportation. Each box takes 11 days to complete, and the entire build of eight boxes was completed in three weeks.

Quality control is essential in Passive House construction, due to the construction detailing and superior air sealing that are required to meet the stringent standard. By building in a factory environment, Beracah is able to achieve these air sealing targets as all trades are part of an integrated team that is experienced working together.